Industrial Control Wiring: Reliable Systems for Peak Performance

Supporting Complex Automation and Control Systems

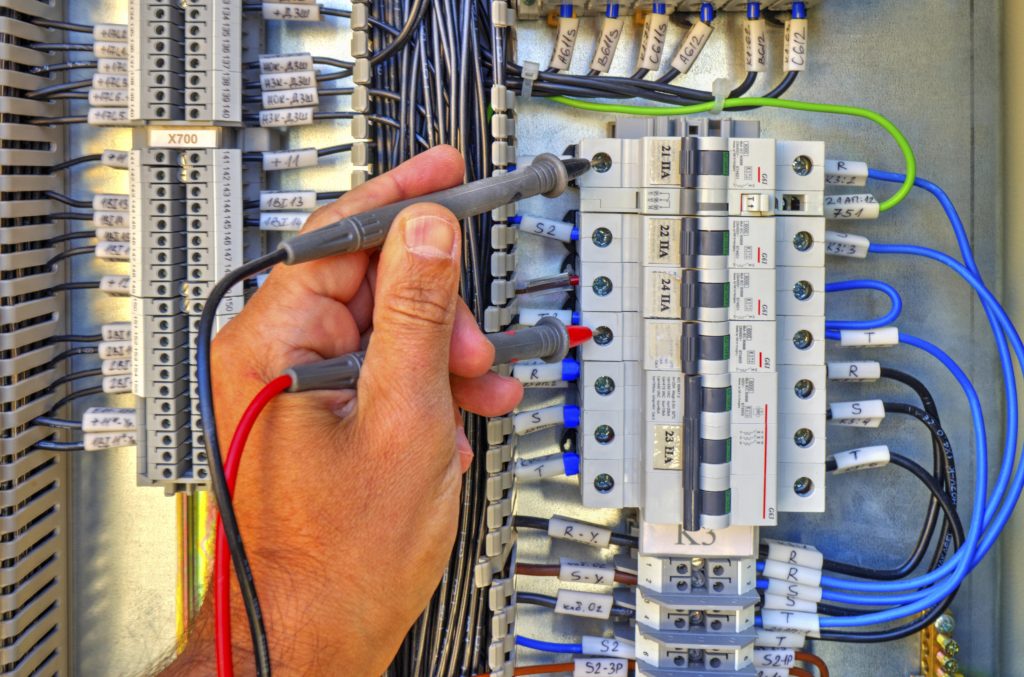

As a part of our full industrial electrical services HUGO offers all aspects of control wiring operations: low-voltage wiring used to carry signals between electrical components like motors, sensors, PLCs, relays, switches, and control panels. It ensures machines start, stop, operate, and respond correctly based on your automation logic and safety protocols. HUGO specialists will ensure that control wiring handles all operational commands, feedback, and interlocks as expected, making it essential for precise, safe, and efficient operations.

Custom Control Wiring Solutions for Industrial Facilities

- Custom Control Panel Wiring, which includes wiring for starters, contactors, relays, timers, safety devices, etc. Neat, labeled wiring for easy troubleshooting and organized per schematics.

- Machine-to-Machine Control Integration Wiring between machines and control systems (PLCs, HMIs, drives). Multi-conductor, shielded cabling for noise-sensitive applications. Protocol-specific cabling (Ethernet/IP, Modbus, PROFIBUS, etc.)

- Start/Stop Stations & Safety Circuit Wiring

- E-Stop wiring, guard switches, safety interlocks, light curtains; Lockout/tagout (LOTO)-compliant control circuits

- Remote I/O and Field Device Wiring (Wiring to and from proximity sensors, photoeyes, limit switches, valves; Cable tray or conduit routing for long-run field devices; Outdoor-rated or hazardous-location (Classified area) wiring

- Troubleshooting & Testing (Circuit continuity testing and signal verification; Relay logic testing and component replacement; Troubleshooting of non-functioning control loops or communication loss)

- Control Circuit Modifications & Retrofits

- Upgrades to relay logic or integration with PLC automation

- Rewiring for machine reconfiguration or process change

- Adding interlocks or modifying the sequence of operations

HUGO electricians guarantee the precision of wiring that eliminates control errors and improves system reliability, run fast and clear diagnostics that minimizes the downtime.

Our expertise includes various services for control wiring

- Pneumatic and hydraulic control systems

- Lifting and lowering system controls

- Refrigeration process management

- Advanced process controls

- Emergency shutdown and safety systems

- Conveyor system automation

- Start-stop stations and limit switch integration

Why electrical supervisors choose to work with HUGO

When we take over the project, we know what the customer expect – quality and guarantee. Our quality control ensures we catch any mistake before you do, so your experience is problem-free. HUGO guarantees:

- Custom Solutions

- Expert Installation

- Safety By Default

- Long-Term Support

Call for a consultation or fill up the request form below and our technician will be reaching out to you shortly.

Request a Quote Today

Location:

Email:

mcoatsworth@hugoelectrical.com